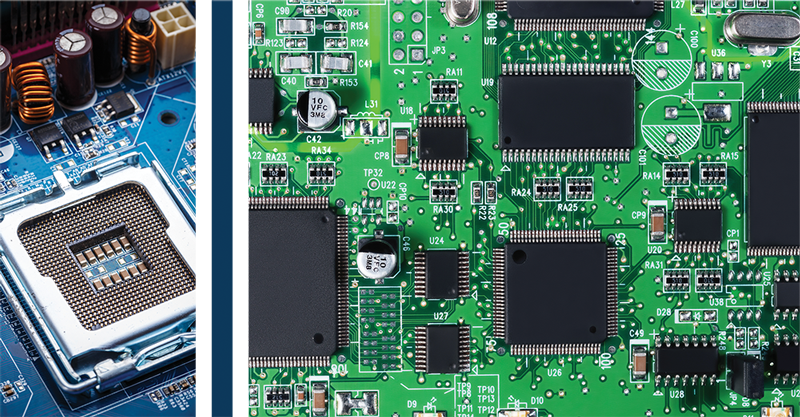

Manufacturer of Printed Circuit Board Assemblies

Rely on our decades of industry experience to provide an intelligent response for all your Electronic Manufacturing needs.

Manufacturer of Printed Circuit Board Assemblies

Rely on our decades of industry experience to provide an intelligent response for all your Electronic Manufacturing needs.

Industries Served

We provide Prototype to Production services for a wide range of industries.

Automotive

Alternative Energy

Industrial

Commercial

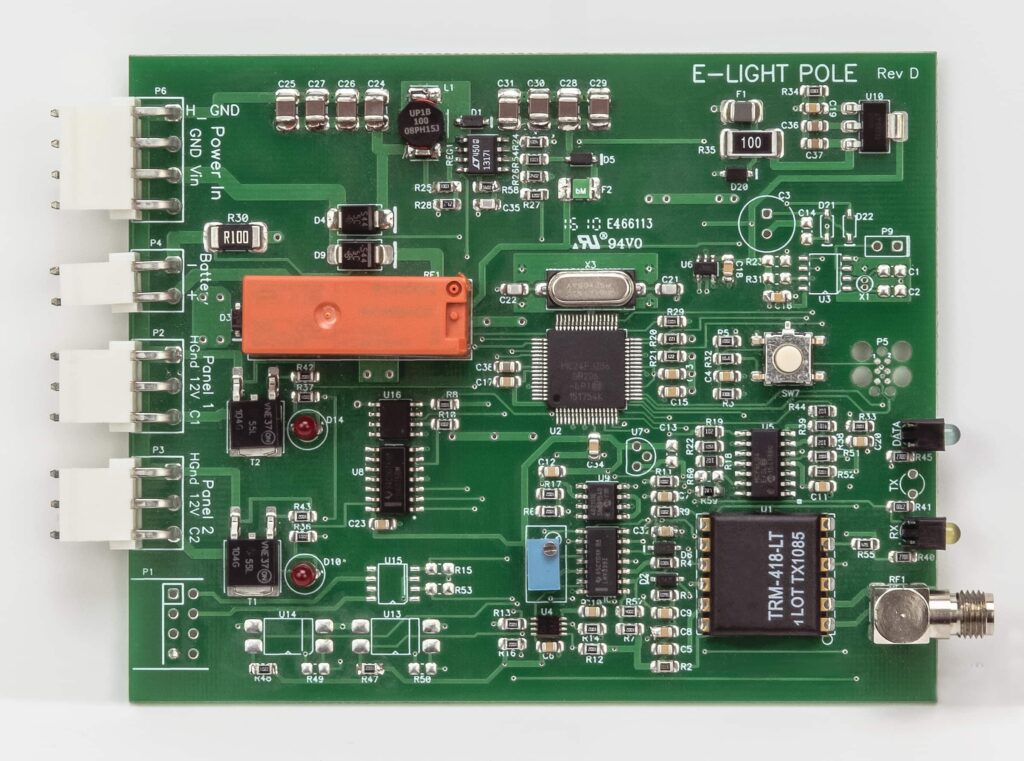

LED Lighting

Communications

Celebrating 40 Years of Business!

Our skilled personnel will use state of the art equipment to complete each manufacturing requirement. Our philosophy is that reliable performance is the result of successfully coordinating a variety of processes and giving proper attention to every aspect. Attention to detail will ensure customer satisfaction and a job well done.